When a motor drive goes down, production often grinds to a halt. How do you find and resolve the problem quickly?

When that variable frequency drive (VFD) goes down, you're under pressure to get it back online. Don't let this pressure make you take even longer to resolve the problem. Instead, remember the VFD troubleshooting checkpoints: check the basics (the controller display, connections, and temperatures), check the motor, and check the drive - then check a little closer.

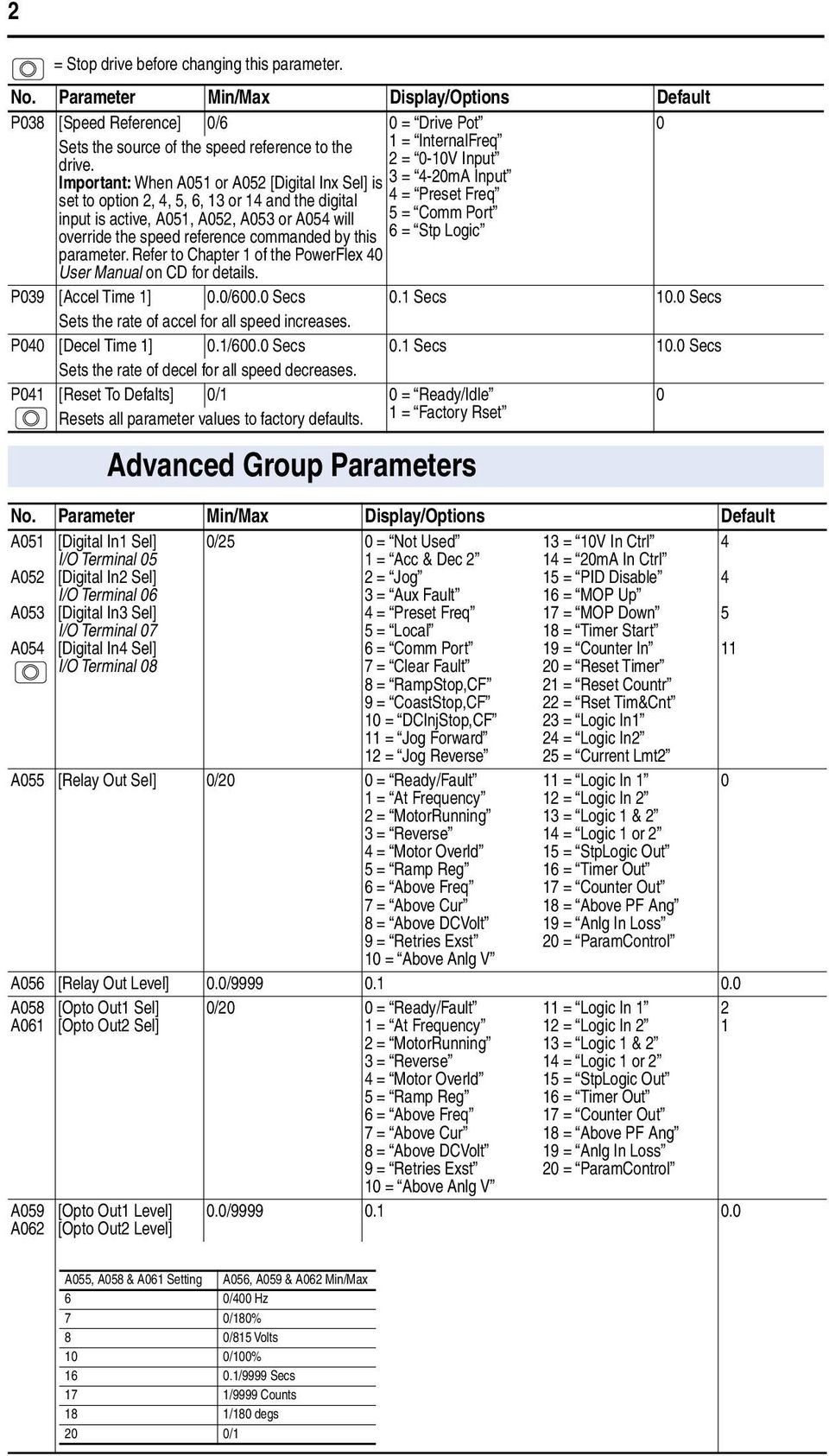

Programming of Basic Parameters: Operating Voltage Frequency Motor Full load current Min. Frequency Start source Speed reference Relay Output Etch. The only other North American and EU drives I know of that have not been updated for long enough to still use 7 segment 4 digit displays and fault codes boil down to AB PF4/40/400 and 1336, and Siemens Micromaster with older HIMs, or older Siemens Simoreg DC drives.

Check the controller display. Most VFD controllers include an interface to set up the drive for operation and to display information about its operation, once it's underway. Although the information displayed varies, most controllers tell you about high current (usually including blown fuses and overload trips), high and low voltages on the input and output sides, high temperatures, internal faults, and even offer advanced power diagnostics.

Check the connections. If the fault codes can't help you track down the problem, then check the connections. Loose connections are among the most common causes of faulty operation in VFD applications. Just eyeballing a connection is sometimes enough to know it's loose. You can also check for a voltage drop across the connection if you're still powered up - or resistance through a connection if you're powered down. Don't forget to isolate the connection to get a reliable reading.

Check temperatures. Checking the temperature of connections with a temperature probe or IR-thermometer is one way to tell if they're loose. They should never be hotter than the connecting wires. You can check temperatures in the drive and at the motor. For example, if the motor insulation is unsuitable for VFDs, it'll gradually degrade until it develops a short. Such shorts are often too small to blow a fuse, and too intermittent to trip an overload - but enough to shut down a controller. An IR thermometer can show what's going on. Also, use your nose: If a motor smells hot, it is.

You can do more. But usually, just checking the basics will be enough to uncover any problems you may have and get the system running again. That can give you the time you need for a permanent fix.

Sidebar: Check a Little Closer

In new installations, apparent problems with drive performance are often due to improper application, drive selection, setup, or installation of the motor as well as the drive. Sometimes 'drive problems' are due to process control logic and not the drive at all.

In the case of frequent breaker trips, you may need to examine protection coordination, to ensure your breakers are the right size from the drive back to the service. You may also need to check other branch and feeder circuits. But first, see if your drive can reduce inrush current with a 'soft start' function. Also, you may need to check:

- Current to the motor (ammeter),

- Voltage notching (oscilloscope),

- Inductive noise in signal, control, or power wiring (oscilloscope),

- Cable routing (visual inspection),

- Damaged signal, control, or power wiring (insulation resistance, TDR), and

- Current through the controller during sudden load changes, or during speed ramps (controller display).

Commons Issues with Allen-Bradley PowerFlex Drives

Troubleshooting a faulted drive can be a tough endeavour. We’re here to help! The list below features some of the most common reasons why Allen-Bradley PowerFlex drives can fault and how to solve those issues. If you’ve tried all of the tips below and there’s still an problem with your drive, it might be time to contact your service provider for a repair or replacement. Contact us today for support!

Problems and Solutions for Allen-Bradley PowerFlex Drives

- Contamination/Corrosion

- Disconnect power and remove contamination (metal shavings, dust) with compressed dry air. The Allen-Bradley Powerflex drive should be sent in for service if it’s soaked with oil or other liquid contaminants.

- Loose connections

- Electronics are limited to their wiring. Vibrations, physical manipulation or relocation may loosen terminal connections. Verify and secure all terminal connections.

- Missing power phase

- Check input voltage and verify power is on all phases.

- Bad cables

- Over time and after constant use, cables will wear out from physical damage and contamination. If you have haven’t swapped out your cables in a while, secure a new cable and try again.

- Seized cooling fans

- Overheating is the biggest enemy to electronic circuitry. Proper ventialtion requires that fans have been cleaned and devoid of any debris.

- Wrong parameters

- This issue can occur when system memory leaks due to voltage transients and the values change. Backup the parameters using the HIM and reset the drive to factory default, then restore the correct parameters.

- Binded load

- This will usually cause an overcurrent fault. Check gear, fans, pulleys or worm gears for proper operation.

Allen-Bradley PowerFlex Drives

Alarm Numbers and Descriptions

Powerflex 4 Fault Codes F007

Powerflex 4 Fault Codes

- 2 Auxiliary Input

- 3 Power Loss

- 4 Under Voltage

- 5 Over Voltage

- 7 Motor Overload

- 8 Heatsink Over Temp

- 9 Transister Over Temp

- 12 HW Over Current

- 15 Load Loss

- 16 Motor Thermistor

- 17 Input Phase Loss

- 24 Decel Inhibit

- 25 Over Speed Limit

- 29 Analog In Loss

- 33 Auto Restart Tries

- 36 SW Over Current

- 38 Phase U to Ground

- 39 Phase V to Ground

- 40 Phase W to Ground

- 41 Phase UV Short

- 42 Phase UW Short

- 43 Phase VU Short

- 48 Params Defaulted

- 49 Drive Powerup

- 51 Fault Queue Cleared

- 52 Faults Cleared

- 63 Shear Pin

- 64 Drive Overload

- 71-75 Port 1-5 Adapter

- 77 IR Volts Range

- 78 Flux Amps Reference Range

- 79 Excessive Load

- 80 AutoTune Aborted

- 81-85 Port 1-5 DPI Loss

- 87 IXo Voltage Range

- 91 Encoder Loss

- 100 Parameter Checksum

- 101 User Set 1 Checksum

- 102 User Set 2 Checksum

- 103 User Set 3 Checksum

- 104 Power Board Checksum 1

- 105 Power Board Checksum 2

- 106 Incompatible MCB-PB

- 107 Replaced MCB-PB

- 108 Analog Calibration Checksum

- 111 Enable Hardware